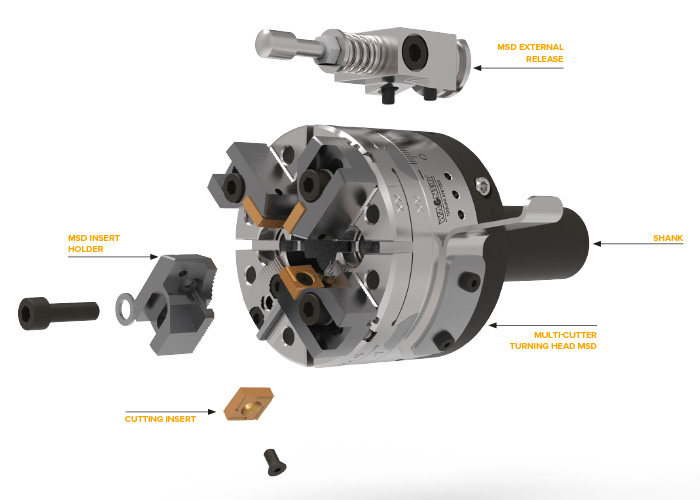

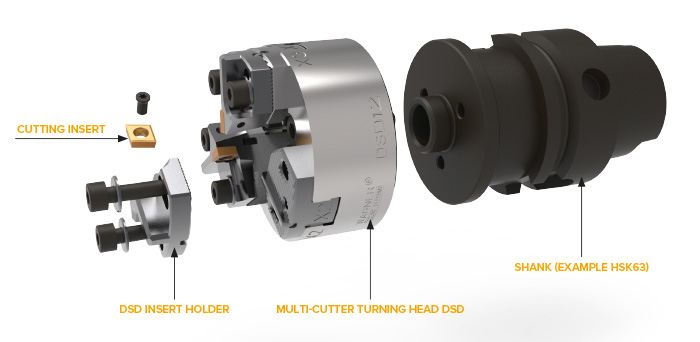

MULTI-CUTTER TURNING SYSTEMS

With the Wagner multi-cutter turning systems, workpieces can be reduced in diameter. The starting material can be round, square or hexagonal, drawn or rolled. In addition, all machinable materials can be processed. Depending on the material and the requirements of the turned surface, cutting depths of up to 5 mm can be achieved.

A distinction is made between MSD with four cutting edges and an opening function and DSD with three cutting edges without an opening function.

ADVANTAGES OF MSD AND DSD

- high efficiency due to 3 to 4 times higher feed rate.

- large working range

- easy handling due to central diameter adjustment

- high turning accuracies

- use of DIN-ISO inserts or Wagner precision inserts

ADVANTAGE OF DSD

- very good chip removal

ADVANTAGES MSD

- the cutting forces cancel each other out due to two opposite cutting edges, which means that workpieces with a long chucking length can be machined.

- high surface quality due to original Wagner opening function. When the turning length is reached, the four carbide cutting inserts are lifted off the workpiece as the tool opens. The contact-free return ensures a score-free workpiece.

| TYPE | Number of cutting edges | Turning-Ø mm | Tool Ø mm | Opening function | Tool length mm | Weight kg |

|---|---|---|---|---|---|---|

| MSD20 | 4 | 2–16 (20) | 70 | yes | 75 | 1.7 |

| MSD20R | 4 | 2–16 (20) | 70 | yes | 82 | 2.0 |

| MSD30 | 4 | 16–30 | 84 | yes | 75 | 2.1 |

| MSD30R | 4 | 16–30 | 84 | yes | 82 | 2.8 |

| DSD12 | 3 | 1–12 | 55 | no | 40 | 0.9 |

| DSD16 | 3 | 2–16 | 70 | no | 48 | 1.4 |

R: for rotating use

DSD: suitable for rotating and stationary use

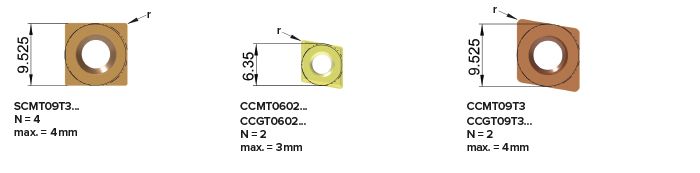

CUTTING INSERTS

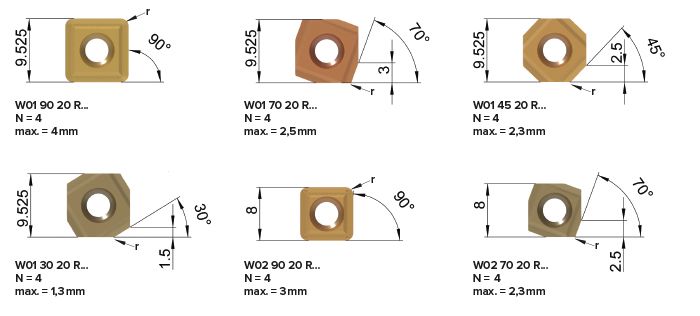

Precision-ground Wagner inserts for MSD and DSD insert holders W01 B5 and W02 B5:

N = number of cutting edges

r = corner radius (on request)

max. = maximum cutting depth (important!)

ISO inserts for insert holders Wagner MSD and DSD Z5: