FROM A TRADITIONAL COMPANY TO AN INNOVATIVE ENTERPRISE

Since 1890, Wagner Tooling Systems has specialized in precision tools for the efficient production of external threads and external machining of all kinds. The proven thread cutting systems and thread rolling systems, whose tradition goes back to the era of Gustav-Wagner-Maschinenfabrik, have been manufactured in Pliezhausen, Germany with exacting quality standards since 1994. In 2018 the company Wagner Werkzeugsysteme was integrated into the Baublies Group under the new name Wagner Tooling Systems Baublies GmbH.

TECHNOLOGY AND DEVELOPMENT

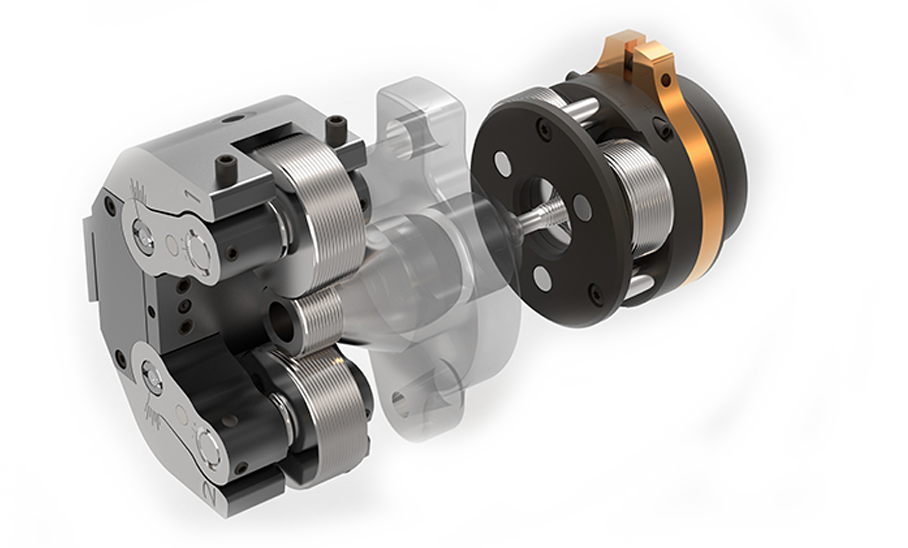

We are transporting the tradition of the Gustav-Wagner-Maschinenfabrik with innovative technology into the future through the further development of our product range consisting of rolling systems axial and tangential, cutting systems and multi-cutter turning systems. Our aim is to develop sophisticated solutions that offer the user maximum economy and durability. Our products, particularly the castors of the thread rolling heads specially developed by Wagner Tooling Systems, as well as our consulting and development services enjoy an excellent reputation among international experts.

The continuous development efforts by our engineers ensure that our technology is always among the world‘s most advanced. Because commitment to innovation is our constant objective! Each of our products is developed and manufactured for you with Swabian precision to meet the growing demands and requirements of the markets.

GUIDLINES FOR EXTERNAL THREAD PRODUCTION

HOW OUR CUSTOMERS BENEFIT

We offer the users of our tools a wide range of standardized and customized solutions. Sophisticated design down to the smallest detail and a large vertical range of manufacture make it possible to provide customers with durable precision tools of the highest quality. All manufacturing processes are certified and subject to continuous quality control. To enable the user to minimize set-up times, we pay attention to easy handling and fast tool changes.

As an additional service, we offer our customers workshops and seminars. There, interested users can learn how to achieve optimum productivity when using roller burnishing technology.

Interested in a workshop?